Big Ted

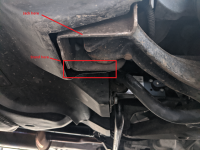

I’ve some planned work to do (brakes) on the Cali later this year once it stops raining, so I’ve been looking at getting a trolley jack and axle stands.

Today the Cali has VW sidebars fitted and is on standard springs and shocks, but will be fitted with some B14’s in a month or so.

I believe a 2 tonne jack will be enough, 3 even better, but I’m unsure if I will need a low entry one or a high lift, or even both?

Assuming a flat tyre, would a standard trolley jack fit under the body once B14’s are fitted?

This kit looks cheap and cheerful, with decent axles stands. (I’m not looking for professional grade kit, just DIY’er level)

www.sgs-engineering.com

www.sgs-engineering.com

Any thoughts?

Today the Cali has VW sidebars fitted and is on standard springs and shocks, but will be fitted with some B14’s in a month or so.

I believe a 2 tonne jack will be enough, 3 even better, but I’m unsure if I will need a low entry one or a high lift, or even both?

Assuming a flat tyre, would a standard trolley jack fit under the body once B14’s are fitted?

This kit looks cheap and cheerful, with decent axles stands. (I’m not looking for professional grade kit, just DIY’er level)

SGS 2 Tonne Car Trolley Jack | 4 Tonne Ratchet Axle Stands

A short wheel base chassis makes this exceptionally priced trolley jack ideal for keeping in your car boot.

Any thoughts?