pjm-84

Super Poster

VIP Member

- Messages

- 2,698

- Vehicle

- T5 SE 180

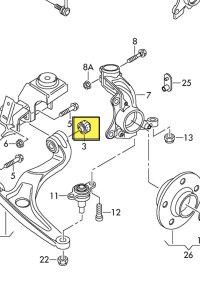

Need to swap mine out. Did the ball joints a few days ago and noted some swarf coming out with one of the M14s. Thought it odd, but it didn't register, and I assumed it was from the ball joint (that needed replacing). Torqued to 50nm fine (Autodoc) but I note the VW requires 90nm + 45 degree, so went to re-torque last night and it stripped about 45degrees beyond 50nm and no where approaching 90nm. Wasn't happy with 50nm and thought this low, hence the check.

No great shakes and I glad I've caught this. Had suspension work undertaken by 3 other garages and the assumption would be it was gunned in previously , maybe missaligned. The others were tight and the other side super tight requiring a bigger power bar to remove.

So with the background over. Does anyone know who supplies VW for this item before I order a replacement from LLL part for a geniune one ?

VW pricing is stupid and LLL want £423 for the knuckle. But it would be annoying to find out its supplied by a third party to VW which I can buy at a cheaper rate.

No great shakes and I glad I've caught this. Had suspension work undertaken by 3 other garages and the assumption would be it was gunned in previously , maybe missaligned. The others were tight and the other side super tight requiring a bigger power bar to remove.

So with the background over. Does anyone know who supplies VW for this item before I order a replacement from LLL part for a geniune one ?

VW pricing is stupid and LLL want £423 for the knuckle. But it would be annoying to find out its supplied by a third party to VW which I can buy at a cheaper rate.