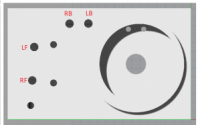

All the letters in the schematic are referenced to letters to the external ports on the manifold according to the picture below.

Pump in and out port is actually int the center of the big circular feature. I have not drawn that detail.

Here is what I believe the various components are:

A = 3 way Spool valve

B = Ball check valve

C = Pilot operated check valve? Side 1

D = Directional valve for pump flow? Side 1

E = 3-way spool valve

F = Emergency close valve

G = Directional valve for pump flow? Side 2

H = Pilot operated check valve? Side 2

I = Adjustable restrictor or ball check valve

J = Adjustable restrictor or ball check valve

K = Pilot operated check valve

L = Pilot operated check valve

M = Ball check valve

N = Ball check valve

O = suction pipe

P = adjustable restrictor or ball check valve

Q = adjustable restrictor or ball check valve

Ram connection ports:

RF = Right Front

RB = Right Back

LF = Left Front

LB = Left Back

BTW, I have tried cleaning the manifold as good as possible using brake cleaner (isopropyl alcohol basically) in combination with compressed air. I don't know if it helped or not but could not see any obvious debris exiting from anywhere.

View attachment 60433