jjpoppy

Lifetime VIP Member

Hi can anyone help please.

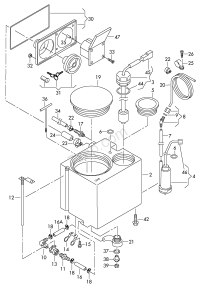

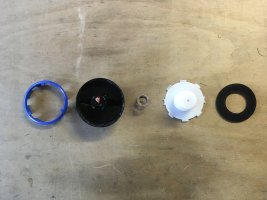

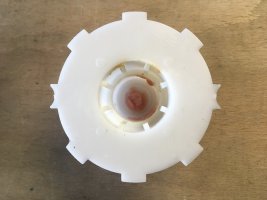

The fresh water tank on my Ocean is not venting.

After using the pump when I remove the filler cap I can hear the air pressure equalising.

Van is out of warranty period so its down to me!

Where is the vent tube? can I get to it to clear it? Would a small hole drilled through the inner part of the filler cap work?

Regards in anticipation of assistance.

The fresh water tank on my Ocean is not venting.

After using the pump when I remove the filler cap I can hear the air pressure equalising.

Van is out of warranty period so its down to me!

Where is the vent tube? can I get to it to clear it? Would a small hole drilled through the inner part of the filler cap work?

Regards in anticipation of assistance.