Hi Bigbud,

Been using the pod almost a year now and still very pleased with it. Since the original posts were made I have:

Sorted out mains hookup under the rear bumper (detailed on another thread).

Added a shelf on the left hand side to hold cups & crockery.

Added a low shelf on the right hand side. Camping pots fit underneath and a fabric box fits above.

Changed the black webbing strap for a blue one to match the door rails (what a colour tart!)

That’s about it really.

Overall it all works quite efficiently, the fabric boxes allow me to pack in the house and just transfer to the van if going out for the day or longer. For short and day trips the single burner is enough to heat up meals or make tea/coffee. On longer trips I use a Camping Gaz ‘Party Grill’ outside the van as an additional cooking source, it can work as either a grill or large burner. With the small canisters gas is expensive per g but then the stove was only £25 rather than the £300ish of a proper plumbed in setup so that difference will buy a lot of canisters. The coolbox is a fantastic bit of kit, also really useful for day to day shopping.

What I have noticed is a lack of worksurface when both flaps are open. If I was going to rebuild I would make the right hand side a fixed top and have a large drawer underneath. I don’t miss having a fixed sink at all. Sliding doors are great and allow access. I can still get at most of the storage when the bed is made (enough to make breakfast in bed anyway

). They took quite a bit of fiddling to slide smoothly and not rattle though.

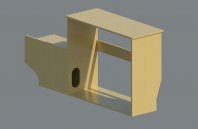

I have started making another unit that will fit behind the coolbox in the rear of the van. Basically extending the run of units back to the tailgate. Did consider a wardrobe but have gone for a much lower storage box to gain myself worksurface and also maintain visibility out of the nearside rear quarter when driving. The idea is that this will bolt to the multiflex board and be used on longer trips. Over the year I have mellowed to the multiflex board. I got a protector made for it and now find it perfect for laying a bike on. Bike is then inside the van and I don’t need to worry about security quite as much. For longer trips or if using the muddy MTB I will still fit the bike rack.

Other task at some point is to fit some dedicated wiring back to the leisure battery rather than using the 12v power socket. Will then be able to use thicker cable and not get so much of a voltage drop to the coolbox. While doing that I will put a dedicated CTEK charging socket in and maybe a battery monitoring gauge

Still going through retrofit heating options as you have prob seen from that thread! That’s one job I won’t be doing myself.