Max-Felix

Top Poster

VIP Member

Hopefully it might be of interest to others but I will start work on this this week and will document the build here.

I pick up the Beach in a few days but nearly bought one a year ago and always planned a kitchen unit so have the plan ready. It will be removable but would mostly be designed to stay in situ so the Beach is always 'ready to go'. Over the time I have gathered a ridiculous amount of pictures, plans, links, suppliers, pieces of info etc, many from here of course and special thanks to Owen for his help with sharing plans and info.

Time is short as I only have two weeks or so to finish this alongside normal work. As I say countless hours of research and planning comes down to a simple plan and relatively simple unit but it still has to look 'professional' and work well. We lived in a simple T25 VW for 6 months as twenty-somethings and that taught us a lot too about what is really needed in a camper.

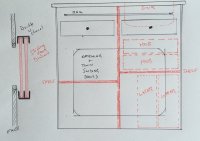

I'm not going to cut any wood until I have the Beach here to double check measurements but a cardboard full size mock up is the first real start, see below.

Unit will be 800mm wide to include two halves as such. I'm not installing a built in hob as we envisage cooking outside the majority of the time and to install a Smev hob (properly/safely) you then need a sealed gas compartment, drop out hole through the floor etc. No time, space or inclination to drill the floor but the option remains for the future to add this. So there will be two gas cartridge stoves - been a big fan of these for years, they work well, are powerful, almost disposable (£10 each) when they get too grotty and if you buy in bulk the cartridges can actually work out cheaper than 907's.

We will have a small SMEV sink built in (8005 to allows space on the left for a future hob or cartridge stove) as we like running water in the 'van. Two 10 litre containers for fresh/waste. Ideally I would just drain to the outside/bucket to save waste space and hassle but again cannot bring myself to drill the mint Beach floor!

Two drawers as always useful and below there general cupboard space.

Anyway, pics and more text will hopefully show the ideas more.

I pick up the Beach in a few days but nearly bought one a year ago and always planned a kitchen unit so have the plan ready. It will be removable but would mostly be designed to stay in situ so the Beach is always 'ready to go'. Over the time I have gathered a ridiculous amount of pictures, plans, links, suppliers, pieces of info etc, many from here of course and special thanks to Owen for his help with sharing plans and info.

Time is short as I only have two weeks or so to finish this alongside normal work. As I say countless hours of research and planning comes down to a simple plan and relatively simple unit but it still has to look 'professional' and work well. We lived in a simple T25 VW for 6 months as twenty-somethings and that taught us a lot too about what is really needed in a camper.

I'm not going to cut any wood until I have the Beach here to double check measurements but a cardboard full size mock up is the first real start, see below.

Unit will be 800mm wide to include two halves as such. I'm not installing a built in hob as we envisage cooking outside the majority of the time and to install a Smev hob (properly/safely) you then need a sealed gas compartment, drop out hole through the floor etc. No time, space or inclination to drill the floor but the option remains for the future to add this. So there will be two gas cartridge stoves - been a big fan of these for years, they work well, are powerful, almost disposable (£10 each) when they get too grotty and if you buy in bulk the cartridges can actually work out cheaper than 907's.

We will have a small SMEV sink built in (8005 to allows space on the left for a future hob or cartridge stove) as we like running water in the 'van. Two 10 litre containers for fresh/waste. Ideally I would just drain to the outside/bucket to save waste space and hassle but again cannot bring myself to drill the mint Beach floor!

Two drawers as always useful and below there general cupboard space.

Anyway, pics and more text will hopefully show the ideas more.