D

Doug Curran

VIP Member

As a new (to me) owner of a used T5 Ocean, as I poured over various forums, I read many complaints about wear of the camshaft and head, with lots of replacements undertaken. What I didn't come across - other than cautions regarding the faithful use of the VW spec oil, was a broad recognition of the inherent engineering defect of VW to not control the movement and rocking of their PD injectors. The clamp system on these PD engines (both 4 & 5 cylinder) with its single screw "clamping foot" on only one side, allows the injector to rock back and forth in its bore, eventually wearing semi circular gouges into the bores and sealing surfaces.

The result of this is leakage of fuel (under high pressures) past the injector seals, is dilution of the lubricating oil. This dilution results in the oil failing to protect metal to metal parts, particularly of the high loading found on camshaft lobes and lifters. In severe cases the loss of compression in the cylinder results in hard starting and low performance.

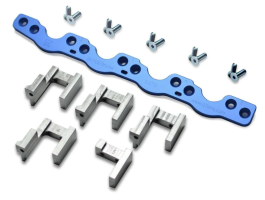

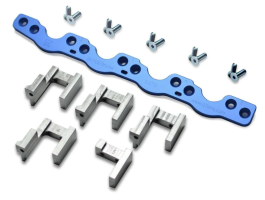

It was only recently that I became aware of a solution that offers a reliable upgrade to forestall further wear and/or in most cases eliminates the further onset of bore wear and oil dilution, adding tens of thousands of reliable miles to the PD engine: The 07eins 'Ultimate Bridge'

I bought the Ultimate Bridge kit once I realized the critical deficiency of the VW PDE injector design and it's prone to failure to the engine due to oil dilution. The 07eins units are beautifully and precisely machined to eliminate the injectors rocking in their bores. It's regrettable that VW did not have the brains to engineer around a problem that can shorten or completely destroy the diesel engines in their vehicles. More people need to be made aware of the inherent defect of these engines. The 07eins kit is precisely assembled, with clear instructions and videos to make installation painless for DIY home mechanics.

Realizing that many Calis with the older PD engines are nearing the end of their useful life, it would still make sense to install one of these kits on an aging engine - or a new rebuilt unit - as it prevents the onset of this factory defect that radically shortened the life of the original engines. 07eins will even accept the return of the unit (less consumables/stretch bolts) if it fails to remedy your issues related to the injectors and bore wear. Check out their upgrade of Viton seals for additional protection.

The result of this is leakage of fuel (under high pressures) past the injector seals, is dilution of the lubricating oil. This dilution results in the oil failing to protect metal to metal parts, particularly of the high loading found on camshaft lobes and lifters. In severe cases the loss of compression in the cylinder results in hard starting and low performance.

It was only recently that I became aware of a solution that offers a reliable upgrade to forestall further wear and/or in most cases eliminates the further onset of bore wear and oil dilution, adding tens of thousands of reliable miles to the PD engine: The 07eins 'Ultimate Bridge'

I bought the Ultimate Bridge kit once I realized the critical deficiency of the VW PDE injector design and it's prone to failure to the engine due to oil dilution. The 07eins units are beautifully and precisely machined to eliminate the injectors rocking in their bores. It's regrettable that VW did not have the brains to engineer around a problem that can shorten or completely destroy the diesel engines in their vehicles. More people need to be made aware of the inherent defect of these engines. The 07eins kit is precisely assembled, with clear instructions and videos to make installation painless for DIY home mechanics.

Realizing that many Calis with the older PD engines are nearing the end of their useful life, it would still make sense to install one of these kits on an aging engine - or a new rebuilt unit - as it prevents the onset of this factory defect that radically shortened the life of the original engines. 07eins will even accept the return of the unit (less consumables/stretch bolts) if it fails to remedy your issues related to the injectors and bore wear. Check out their upgrade of Viton seals for additional protection.