briwy

Super Poster

VIP Member

After the rear diff had sprayed oil onto the spare I decided to get it off and clean it and check the pressure etc.

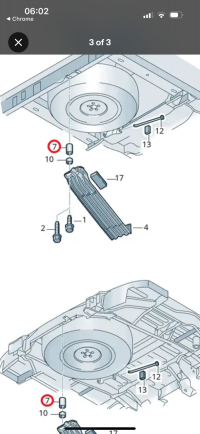

Now I'm fairly handy having built a few cars in my time but what a faff. Took the right hand bolt out and unscrewed the left hand one, slid the carrier sideways so that it dropped to the ground.

No way would the wheel come out from under the van, not helped by the fact that the towbar socket is fairly low. Eventually I jacked it up a bit and got the wheel out.

Getting it back was another problem, managed to get it onto the carrier (back jacked up again) and tried to lift the carrier onto the bolt. The bolt seems to be about half an inch too short so had to get the jack under the carrier to force it up.

Surely there must be an easier way?? Doing this at the side of the road in the rain would be a nightmare.

Has anyone done this??

Perhaps should mention this is a steel spare with a 235 55 17 standard tyre on.

Now I'm fairly handy having built a few cars in my time but what a faff. Took the right hand bolt out and unscrewed the left hand one, slid the carrier sideways so that it dropped to the ground.

No way would the wheel come out from under the van, not helped by the fact that the towbar socket is fairly low. Eventually I jacked it up a bit and got the wheel out.

Getting it back was another problem, managed to get it onto the carrier (back jacked up again) and tried to lift the carrier onto the bolt. The bolt seems to be about half an inch too short so had to get the jack under the carrier to force it up.

Surely there must be an easier way?? Doing this at the side of the road in the rain would be a nightmare.

Has anyone done this??

Perhaps should mention this is a steel spare with a 235 55 17 standard tyre on.