chrissmit

- Messages

- 87

- Vehicle

So it's the big one, not the small one.

I've been doing it all wrong then...

I've been doing it all wrong then...

The Lamp is on a timer...So I think I will leave it and order a new bulb.

LOL very embarrassed to say I found that out.The Lamp is on a timer...

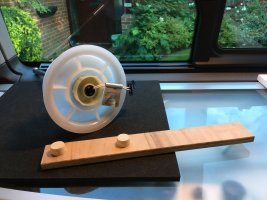

I myself tried everything and at last being completely despaired, constructed this: (which helped immediately)

View attachment 7545

Any tips on how to remove an airlock if that's the problem?Unless you have a need to access the pump or level gauge to replace, as per recommendation from @WelshGas I personally would not remove the access lid. Cleaning the tank can be done adequately by using Milton and flushing. Keeping the system closed is a good start to retaining a hygienic installation. By unnecessarily accessing the tank you may cause more problems than you solve. For instance if you hear the pump run but there’s no water flow, the issue is most likely an air lock rather than a fault with the pump.

Fresh water tank vent

Hi all, just getting to grips with the new Ocean and todays task was sterilise the water system and flush it out, so I dropped in a couple of sterilising tabs, filled up the tank, waited 20 mins and then flicked on the tap and started to run it through. All was working fine until I heard a...vwcaliforniaclub.com

Yes - suck the tap ! Cup your lips over the end of the tap with the pump running, and suck. Someone else on the forum suggested this trick and it worked for me. I’d also remove the filling cap to minimise any negative head on the pump (ie vacuum).Any tips on how to remove an airlock if that's the problem

Thank you very much! Yes that worked and managed to suck some water through the tap. But the pump still didn't kick in unfortunately...Yep,

Yes - suck the tap ! Cup your lips over the end of the tap with the pump running, and suck. Someone else on the forum suggested this trick and it worked for me. I’d also remove the filling cap to minimise any negative head on the pump (ie vacuum).

Agree. It sounds like the pump has failed.Thank you very much! Yes that worked and managed to suck some water through the tap. But the pump still didn't kick in unfortunately...

The pump doesn't make a whirring noise anymore when I open the tap. The tap just makes a faint click and then I get an error message in the overhead console. I checked the 5 amp fuses under the passenger seat and they seem ok. So guess that means the problem must be with the pump itself...?

Thank you very much! Yes that worked and managed to suck some water through the tap. But the pump still didn't kick in unfortunately...

The pump doesn't make a whirring noise anymore when I open the tap. The tap just makes a faint click and then I get an error message in the overhead console. I checked the 5 amp fuses under the passenger seat and they seem ok. So guess that means the problem must be with the pump itself...?

Thanks! Appreciate all your helpAgree. It sounds like the pump has failed.

Great thanks I'll take a lookIf you need help getting at the pump to replace it, then you could take a look at my 'how-to' post on doing a factory shower retro-fit (there may well be faster routes to getting the information you need!):

OEM T6.1 rear shower system

Indeed I have! - I did it at the end of June before heading off for a month's trip where it was well and truly tested and worked a treat. Been a bit busy since, so whilst I did take all the pictures and measurements which I'd need to support a 'how to do it' post, I have just not managed to get...vwcaliforniaclub.com

Aug 17, 2022

OEM T6.1 REAR SHOWER SYSTEM - A GUIDE TO PARTS-SOURCING & FITTING

PART I of V

etc. . . .

I really don’t think Milton will harm stainless steel. Overuse / too strong, and it probably will degrade rubber seals but not silicone seals. This is from 40 years in the beer and drinks manufacturing business, cleaning plant with much higher strength caustic, on a daily basis, or more frequently. The occasional flush through with Milton will be fine.Just be aware that Miltons can react with stainless steel. Puriclean is the better bet.

Just passing on the information , do with it as you please . Google 'milton's and stainless steel'I really don’t think Milton will harm stainless steel. Overuse / too strong, and it probably will degrade rubber seals but not silicone seals. This is from 40 years in the beer and drinks manufacturing business, cleaning plant with much higher strength caustic, on a daily basis, or more frequently. The occasional flush through with Milton will be fine.

Appreciate your concern. I’ve done as suggested. Some posts found on Google I saw quoted standing neat Milton in stainless. I wouldn’t advise this.Just passing on the information , do with it as you please . Google 'milton's and stainless steel'

What van?Any tips on how to remove an airlock if that's the problem?

The VW California Club is the worlds largest resource for all owners and enthusiasts of VW California campervans.