You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Volkswagen T6.1 Ocean Roof Seal Replacement — Gap and Rust Concerns

sidepod

Super Poster

Lifetime VIP Member

- Messages

- 6,957

- Vehicle

- T4 PopTop

No that’s not right! Looks like it just needs pushing on properly?

KevH

Wave at Ruby if you see us

Lifetime VIP Member

Any seal that doesn’t actually seal will allow moisture to ingress.

That seal looks ‘wavy’ on the folded edge suggesting that it is not pushed on enough. It isn’t a task I have myself so I can’t offer any tips however I would give it some priority or risk trapping any moisture already in there.

That seal looks ‘wavy’ on the folded edge suggesting that it is not pushed on enough. It isn’t a task I have myself so I can’t offer any tips however I would give it some priority or risk trapping any moisture already in there.

Van Diesel VW

VIP Member

Why was the seal replaced and if at a garage I would return and advise on a faulty install.“Is it normal for there to be a gap after replacing the roof seal on a T6.1 Ocean? Could it lead to rust problems?”

View attachment 139629

sidepod

Super Poster

Lifetime VIP Member

- Messages

- 6,957

- Vehicle

- T4 PopTop

FFS. Raise the roof a couple of inches, stand on the door foot step and push it back on.

Viktorgeorge

Starlight Blue Ocean 4Mo MY2023 older bellows

Lifetime VIP Member

I have had three of these seals over 2 years and none of them fit perfectly at this specific area, but all certainly fit better than your photo. Elsewhere on the pop up roof the fit is tight.

One of the problems with this section of the seal is that it has to be moulded to the two ‘ridges’ at the front, but whilst the seal has an integral steel ‘spine’ to help it hold its shape, that steel spine is also a potential rust problem as it easily breaks through the rubber.

Fitting a new seal therefore requires great care and is best done it hot conditions. My experiences are described within a separate string, which is full of useful information from forum members:

Post in thread 'Avoiding roof corrosion?'

https://vwcaliforniaclub.com/threads/avoiding-roof-corrosion.22428/post-641856

One of the problems with this section of the seal is that it has to be moulded to the two ‘ridges’ at the front, but whilst the seal has an integral steel ‘spine’ to help it hold its shape, that steel spine is also a potential rust problem as it easily breaks through the rubber.

Fitting a new seal therefore requires great care and is best done it hot conditions. My experiences are described within a separate string, which is full of useful information from forum members:

Post in thread 'Avoiding roof corrosion?'

https://vwcaliforniaclub.com/threads/avoiding-roof-corrosion.22428/post-641856

Last edited:

Kayleigh

In the Beach, at the beach

Top Poster

Lifetime VIP Member

No it’s not normal, but also not normal for a T6.1 to need a new roof seal I would say.“Is it normal for there to be a gap after replacing the roof seal on a T6.1 Ocean? Could it lead to rust problems?”

Viktorgeorge

Starlight Blue Ocean 4Mo MY2023 older bellows

Lifetime VIP Member

@Kayleigh, I had three different seals within a year and I recall @Perfectos had even more!No it’s not normal, but also not normal for a T6.1 to need a new roof seal I would say.

The rubber element is much longer lasting but if the seal is handled wrongly (as mine proved to be, twice) it needs replacing. I have also found, two years on, that my procedure of tape to the front roof edge and annual seal removal (when in warm sunshine) cleaning and light brushing in of Lanoguard grease - all as per the link in my previous post - has kept my seal problem free for the last two years.

There does seem to have been more of a problem with recent seals. I recall that @WelshGas checked his seal annually for 12 years or so without corrosion issues.

If for example you get firm with one of the current seals using a rubber hammer to shape it around the front ‘bumps’ in the roof I can guarantee you will reap the consequences.

Careful removal when warm, and then close scrutiny of the inside groove of the seal particularly the front part, to see if there is any ‘break out’ of the steel reinforcing spine would be my advice to anyone who wants to reduce the risk of roof corrosion later. And of course careful replacement afterwards ideally with the front roof edge taped (VW do a tape* and I will check for the reference number though electrical tape is probably just as good) and something like Lanoguard grease.

*Added:

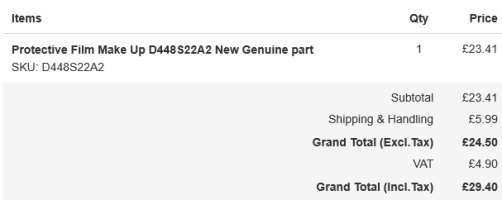

The tape appears as ‘protective film’ under reference 35. Her are some links:

https://www.lllparts.co.uk/catalogs/vw/RDW/CAMP/1058/8/875/875010

Protective Film Make Up D448S22A2 New Genuine part

Deutscheparts specialise in the supply of genuine car parts & accesories for Volkswagen, Audi, Skoda and Seat cars and vans.

I would not be surprised if, in a few years time, this forum is replete with later T6.1 California discovering bubbling paint etc. on the edge of their aluminium pop top roofs. The problem is so obviously waiting to happen.

Last edited:

sidepod

Super Poster

Lifetime VIP Member

- Messages

- 6,957

- Vehicle

- T4 PopTop

The roof edges are taped from the factory.

Kayleigh

In the Beach, at the beach

Top Poster

Lifetime VIP Member

Thanks for commenting. Hadn’t realised it could be so bad with later Californias as the front is taped. I guess the real problem is that without regular checks it’s hard to tell if there is a problem until it’s too late. But the more you check the more chance there is of damaging the existing seal, hence the replacement.@Kayleigh, I had three different seals within a year and I recall @Perfectos had even more!

The rubber element is much longer lasting but if the seal is handled wrongly (as mine proved to be, twice) it needs replacing. I have also found, two years on, that my procedure of tape to the front roof edge and annual seal removal (when in warm sunshine) cleaning and light brushing in of Lanoguard grease - all as per the link in my previous post - has kept my seal problem free for the last two years.

There does seem to have been more of a problem with recent seals. I recall that @WelshGas checked his seal annually for 12 years or so without corrosion issues.

If for example you get firm with one of the current seals using a rubber hammer to shape it around the front ‘bumps’ in the roof I can guarantee you will reap the consequences.

Careful removal when warm, and then close scrutiny of the inside groove of the seal particularly the front part, to see if there is any ‘break out’ of the steel reinforcing spine would be my advice to anyone who wants to reduce the risk of roof corrosion later. And of course careful replacement afterwards ideally with the front roof edge taped (VW do a tape* and I will check for the reference number though electrical tape is probably just as good) and something like Lanoguard grease.

*Added:

The tape appears as ‘protective film’ under reference 35. Her are some links:

https://www.lllparts.co.uk/catalogs/vw/RDW/CAMP/1058/8/875/875010

View attachment 139655

Protective Film Make Up D448S22A2 New Genuine part

Deutscheparts specialise in the supply of genuine car parts & accesories for Volkswagen, Audi, Skoda and Seat cars and vans.www.deutsche-parts.co.uk

I would not be surprised if, in a few years time, this forum is replete with later T6.1 California discovering bubbling paint etc. on the edge of their aluminium pop top roofs. The problem is so obviously waiting to happen.

Viktorgeorge

Starlight Blue Ocean 4Mo MY2023 older bellows

Lifetime VIP Member

Sorry, @sidepod you are wrong on that point. On mine the front edge had no tape (or protective film as VW call it) only the back and sides. From other posts mine was the normal, though perhaps vans more recent than MY23 have that corrected.The roof edges are taped from the factory.

Viktorgeorge

Starlight Blue Ocean 4Mo MY2023 older bellows

Lifetime VIP Member

I am definitely in disagreement mode today @Kayleigh!Thanks for commenting. Hadn’t realised it could be so bad with later Californias as the front is taped. I guess the real problem is that without regular checks it’s hard to tell if there is a problem until it’s too late. But the more you check the more chance there is of damaging the existing seal, hence the replacement.

I think the more you check, clean and treat the seal, carefully along the lines I suggest, the better your chances are of avoiding the problems. @WelshGas (aka the sage) made an interesting a point a whilst back, suggesting that regular treatment of the seal to avoid it adhering to the roof below the pop top might be helpful. His suggestion being that perhaps if the seal starts to attach itself to the roof below, then roof operation will cause the seal to slip a little and with dust and grit be abrasive on the aluminium etc. etc.

I tried to find that @WelshGas post but failed, I suspect he put it better than me. A search under ’Roof Corrosion’ yields many results.

Last edited:

WelshGas

Retired after 42 yrs and enjoying Life.

Super Poster

Lifetime VIP Member

It's me. Yes, when camping roof up, tree sap whatever on the roof where the rubber seal contacts can build up and basically glue the seal to the roof. When this happens opening the roof moves the seal until it is pulled off/up by the roof. Cleaning the area of contact using warm soapy water or Tar Remover, applying a good polish and also treating the seal, stops it adhering and the pull/push of the seal when opening/closing the roof.I am definitely in disagreement mode today @Kayleigh!

I think the more you check, clean and treat the seal, carefully along the lines I suggest, the better your chances are of avoiding the problems. @WelshGas (aka the sage) made an interesting a point a whilst back, suggesting that regular treatment of the seal to avoid it adhering to the roof below the pop top might be helpful. His suggestion being that perhaps if the seal starts to attach itself to the roof below, then roof operation will cause the seal to slip a little and with dust and grit be abrasive on the aluminium etc. etc.

I tried to find that @WelshGas post but failed, I suspect he put it better than me. A search under ’Roof Corrosion’ yields many results.

sidepod

Super Poster

Lifetime VIP Member

- Messages

- 6,957

- Vehicle

- T4 PopTop

Tenuous ?

sidepod

Super Poster

Lifetime VIP Member

- Messages

- 6,957

- Vehicle

- T4 PopTop

I’ll happily bet the only vans that potentially have an issue, is those left outside in the elements 365.

Keep it under cover when not on use and all will be fine.

Keep it under cover when not on use and all will be fine.

Viktorgeorge

Starlight Blue Ocean 4Mo MY2023 older bellows

Lifetime VIP Member

It sure what you mean, @sidepod. There was nothing “tenuous” about the rusting seal reinforcement on my 7 month old Ocean. As per #80 on the link I posted above. I was sickened!Tenuous ?

sidepod

Super Poster

Lifetime VIP Member

- Messages

- 6,957

- Vehicle

- T4 PopTop

WGs theory is what I was referring to.It sure what you mean, @sidepod. There was nothing “tenuous” about the rusting seal reinforcement on my 7 month old Ocean. As per #80 on the link I posted above. I was sickened!

Viktorgeorge

Starlight Blue Ocean 4Mo MY2023 older bellows

Lifetime VIP Member

Mine was garaged for the first 7 months from new (October 2022 to May 2023), in the UK and Portugal, and I got the rust as per post #80, so sorry, but I sadly win that bet!I’ll happily bet the only vans that potentially have an issue, is those left outside in the elements 365.

Keep it under cover when not on use and all will be fine.

https://vwcaliforniaclub.com/threads/avoiding-roof-corrosion.22428/post-641856

Admittedly my ocean would have stood outside in the docks awaiting Europe to UK shipping before I collected it from the dealer but otherwise it was garaged (in superior well ventilated garage conditions).

I have noted this problem seems to be emerging on later T6.1, and perhaps the later seals are defective by comparison. My ‘tenuous’ guess is that the manufacturer or process of the roof seals changed. This could have been a change of the reinforcing material to a lower grade of mild steel or reduction in the depth of rubber cover over it. Alternatively the install of the seals at the factory (there is a tiny video clip see below) changed so that in first fitting the seals the damage sometimes occurred (this could explain my case).

Factory roof seal install at 5 minutes and 39 seconds (just 3 seconds long) here:

I will continue to do annual seal removal and cleaning etc as per my posts above and elsewhere on this subject, and suggest others (particularly of later Californias) might be advised to do the same, along of course with the essential roof drain maintenance described in other posts.

Last edited:

WelshGas

Retired after 42 yrs and enjoying Life.

Super Poster

Lifetime VIP Member

Mine wasn’t garaged for 10 yrs. if not driving or camping it was on my drive and Wales is not renowned for its number of dry days.I’ll happily bet the only vans that potentially have an issue, is those left outside in the elements 365.

Keep it under cover when not on use and all will be fine.

So when it got wet it then dried out instead of sitting idle in a damp or humid garage for days on end.

No galvanic corrosion under the roof perimeter seal or on the windscreen panel when it was sold.

Perfectos

Super Poster

Lifetime VIP Member

My experience is well documented.

In summary: One of Mine was rusty from new, I had 4 seals, over a three year period, had I not checked the seal my roof would now have corrosion. (Resulting corrosion from a rusty roof seal is well documented on all California models). The seal on a T6.1 is identical to T5 !

The tape is a help but it will not prevent the rust causing corrosion once the rust spreads past the tape. The tape is a response from VW to delay the known issue with a roof seal that is not fit for purpose. It delays the issue long enough to make sure the warranty period is over by the time the corrosion is evident

I check the seal annually as suggested above, clean and silicone the rubber no issues now.

In summary: One of Mine was rusty from new, I had 4 seals, over a three year period, had I not checked the seal my roof would now have corrosion. (Resulting corrosion from a rusty roof seal is well documented on all California models). The seal on a T6.1 is identical to T5 !

The tape is a help but it will not prevent the rust causing corrosion once the rust spreads past the tape. The tape is a response from VW to delay the known issue with a roof seal that is not fit for purpose. It delays the issue long enough to make sure the warranty period is over by the time the corrosion is evident

I check the seal annually as suggested above, clean and silicone the rubber no issues now.

Last edited:

Viktorgeorge

Starlight Blue Ocean 4Mo MY2023 older bellows

Lifetime VIP Member

Perfectos was my guru on this. Those who like me are in for long term ownership (I kept my Phaeton from new for 17 years), or who anyway want to protect for future owners, may be wise to follow his advice.My experience is well documented.

In summary: One of Mine was rusty from new, I had 4 seals, over a three year period, had I not checked the seal my roof would now have corrosion. (Resulting corrosion from a rusty roof seal is well documented on all California models). The seal on on a T6.1 is identical to T5 !

The tape is a help but it will not prevent the rust causing corrosion one the rust spreads past the tape. The tape is a response from VW to delay the known issue with a roof seal that is not fit for purpose. It delays the issue long enough to make sure the warranty period is over by the time the corrosion is evident

I check the seal annually as suggested above, clean and silicone the rubber no issues now.

I accept the seal looks identical on T5 to T6.1 but can only again question if its manufacturer or the factory assembly changed because mine was defective from such an early stage (as Perfectos).

Last edited:

C

CaliforniaCylus

VIP Member

I'm about to examine my roof seal and if I need to replace, will probably do it myself rather than through warranty.

Does anyone know how the delivery of the seal works? Is it somehow rolled up into a small package or does it come in a giant bag pre-formed which would make a home install quite difficult...

Does anyone know how the delivery of the seal works? Is it somehow rolled up into a small package or does it come in a giant bag pre-formed which would make a home install quite difficult...

Viktorgeorge

Starlight Blue Ocean 4Mo MY2023 older bellows

Lifetime VIP Member

A DIY examination, first, makes good sense. A hot sunny day, and protected location, is best.I'm about to examine my roof seal and if I need to replace, will probably do it myself rather than through warranty.

Does anyone know how the delivery of the seal works? Is it somehow rolled up into a small package or does it come in a giant bag pre-formed which would make a home install quite difficult...

Hopefully you will not find a problem and you can then clean, treat and carefully replace (no rubber hammering, just work around several times with your hands).

If you do find some rusting, as I did, and are in warranty, it is a predicament. My dealer made things worse (as per my several posts) but then their coachbuilders Rackhams Ipswich (contact Alisdair Ogilvie) were brilliant at making remedy under warranty which with a 7 month old vehicle I wanted to preserve. But if it happened again would I DIY as you are inclined - given my acquired knowledge? Yes probably.

A new seal comes in a large bag and it is as you suggest rolled up. I left mine out as a full rectangle in a warn room for a day or more to take out the 'lumps'. Molding a new seal around the front edge in particular takes time and care, three of us did it a Rackhams together and they left the seal in a 'paint oven' to soften up before we started, plus we used the equivalent of a hair dryer as we shaped the front edge.

If you remove the previously fitted seal and find some rusting, you can always clean that seal and put it back on temporarily as I did, first putting electrical tape over the vulnerable edges as a temporary expedient.

If you take the Lanoguard grease route as I do now, this is best done after a seal has been in place a while and fully taken shape as until the Lanoguard sets it is slippery.

Last edited:

sidepod

Super Poster

Lifetime VIP Member

- Messages

- 6,957

- Vehicle

- T4 PopTop

I considered this Lanoguard type option (my preferred is BelRay waterproof grease), however, given the roof design and ill fitting seal, all of the dirt/sediment that collects in the flutes in the roof panel just gets washed straight into the seal when the van is hosed off/washed. Add grease into the mix and it's gonna get dirty and messy quickly. I just filled the seal groove with ACF50, pushed it back on and wiped off the excess.

It does feel like it needs a seal to seal the seal? Did Perfectos use silicone or similar. Does that not rot the rubber and/or seal in moisture?

Trying not to over think this.

It does feel like it needs a seal to seal the seal? Did Perfectos use silicone or similar. Does that not rot the rubber and/or seal in moisture?

Trying not to over think this.

Perfectos

Super Poster

Lifetime VIP Member

Silicone is a release agent for rubber , it is used to clean rubber and renew seals, a little spray allowed to dry before refitting the seal. Don’t go flooding the groves etc , a little goes a long way and it can be brushed on / into the recesses / profiles of the sealsI considered this Lanoguard type option (my preferred is BelRay waterproof grease), however, given the roof design and ill fitting seal, all of the dirt/sediment that collects in the flutes in the roof panel just gets washed straight into the seal when the van is hosed off/washed. Add grease into the mix and it's gonna get dirty and messy quickly. I just filled the seal groove with ACF50, pushed it back on and wiped off the excess.

It does feel like it needs a seal to seal the seal? Did Perfectos use silicone or similar. Does that not rot the rubber and/or seal in moisture?

Trying not to over think this.

Silicone will slightly swell the rubber and give it a new appearance.

You don’t want the silicone to get all over the paintwork

Gummi Pfledge is another product that can be used to good effect to clean and restore rubber.

What Rots rubber is Petroleum based greases

Silicone is inert and is used as a grease for o rings etc that work at high pressure, the grease keeps the seal supple

It also displaces water

The sliding window seals, door seals gators etc etc benefit from either silicone or Gummi pfledge several times a year

Similar threads

J

- Replies

- 21

- Views

- 6K

B

- Replies

- 14

- Views

- 2K

S

- Replies

- 7

- Views

- 586

About us

The VW California Club is the worlds largest resource for all owners and enthusiasts of VW California campervans.