Ben Nevis

You are of course free to ask VW customer service yourself if you have any doubt - just as I did. Then make your own decision.Let's hope you are right.

You are of course free to ask VW customer service yourself if you have any doubt - just as I did. Then make your own decision.Let's hope you are right.

No I can’t but I am not a crash investigator, all I was saying is for the sake of a few quid a year is it really worth saving money on!Can you provide any actual examples of brake failure due to 20,000 mile 4year old fluid?

Strange also that in the USA (land of litigation), manufacturers have actually removed the requirement to replace brake fluid on service schedules.Strange that the condition of the brake fluid apart from obvious contamination is not even mentioned in the MOT test, it could be ancient and the inspector would be completely happy, yet on here it is a death sentence not to change at 3 year intervals, does not compute.

And you’d trust the yanksStrange also that in the USA (land of litigation), manufacturers have actually removed the requirement to replace brake fluid on service schedules.

| Temporary Brake Failure | ||

The phenomena of having a brake "pedal to the floor" experience is not confined to car chases in old B movies. Although it is not a situation that every motorist has experienced it is one that is certainly happening to more and more drivers. Any make or model of car or van with hydraulic brakes is capable of this type of failure but it is most commonly found on front wheel drive cars. The phenomena described can occur regardless of whether the vehicle has an Antilock Brake System (A.B.S.) or not, although front disc and rear drum or four wheel disc brake systems utilising diagonal split brake designs are most prone to this fault. Traditionally a "by-passing" master cylinder is blamed as the cause of "pedal to floor" problems but by far the greatest cause of this type of failure can be attributed to Glycol based (normal) brake fluid that has been contaminated by moisture, the higher the moisture content the lower the fluid boiling point can become. A feature of brake fluid not commonly recognised is that it deteriorates over time. The main reason for deterioration is that brake fluid is hygroscopic, that is, it absorbs moisture from the air. Because of the heat produced by friction when brakes are operated, brake fluid is designed to have a high boiling point, typically about 265°C / 509°F. Any moisture absorption could find this temperature reduced to a mere 140°C / 284°F over a period of two years. At this level, any period of sustained braking could produce enough friction to bring the fluid to the boil, where it vapourises, leaving the driver with little or no brakes. Unlike engine oil which should be changed according to the distance driven, brake fluid deteriorates not with distance but with time. It continues to absorb water even when the vehicle is stationery. Most vehicle manufacturers recommend regular brake fluid changes on a time basis, e.g. every year. Unfortunately, such recommendations are not always followed and independent surveys have shown that many vehicles have dangerous brake fluid in them. | ||

| Causes of Abnormal Overheating | ||

Binding Brakes - Whether over adjusted or sticking brake parts including handbrake cables, calipers and wheel cyclinder pistons, also master cylinder valves sticking due to corrosion etc. causing residual pressure within the system. Operator Error - Examples of this are the parking brake not fully released or the driver resting his/her foot on the brake pedal. Brake Lining Material - The new type of non asbestos brake lining friction material allows greater dissipation of heat from either the disc or drum into the caliper pistons or brake cylinders. | ||

| Investigation - Post Accident | ||

The heat in the wheel cylinder / caliper is not immediately lost to atmosphere but is actually increased due to heat saturation from the greater heat in the disc or drum. The problem should still exist for at least 5 minutes and possibly up to 20 minutes dependant on conditions, immediate testing will prove ro disprove the driver's story. Another factor to be considered is that when a vehicle is stopped, after a period of sustained braking, then the journey continued heat transference can cause the brake fluid to boil. If the braking system has not been touched but left to cool until the vapourised fluid has condensed once again into liquid form, a very slight vacuum can occur within the system, to normalise the system would require the brake pedal to be depressed at least twice which causes a corresponding drop in the reservoir fluid level. However because of differing brake types this cannot be assumed to be the sole reason for disclaiming the fluid as a cause. Over-heated brakes have a distinct pungent acidic smell, therefore vehicles with drum brakes should be transferred to a building with restricted ventilation, when the rear drums are removed the odour will not only be obvious but it will also linger. In cases of moderate over-heating the brake drum, to the untrained eye will appear normal, correct examination of the inside of the drum will highlight the fact that it is polished smoothly and slightly dark blue on colour. The friction material will become darker and have a polished glazed appearance, any paint ot varnish on the shoe metalwork will be oxidised and appear dull with a blue tint. The utilisation of a small mirror and a source of light reflected onto the shaded friction material will enable a close examination of the lining surface to take place, under these conditions both the glazing and the effects of the bonding agent evaporation are more pronounced. When extreme over-heating occurs the disc pads will turn white at the edges, more so if the pad is not adjacent to a heat absorbing caliper piston. The varnish / paint on the steel backing of the disc pads will usually bubble or flake, except when they are not adjacent to the caliper piston, in that instance the steel backing will turn a dirty white or grey. The friction material touching the disc will be glazed though it can also develop a rough appearance as the material breaks down and transfers between the two. Extremely hot disc pad friction will have the appearance of black carbon crystal and the metal backs will appear pock-marked with fresh rust. The disc surface will be extremely rough and gouged with a fresh rust coating. Dust boots will be charred, the inside rubber seals will be degraded and leaking and the burning pads will leave a deposit of carbon soot. | ||

| Glossary | ||

Brake Fade - If brakes are used to the point of over-heating, the co-efficient of friction is reduced until virtually no friction or stopping power exists between the friction material (pads and shoes) and the discs or brake drums. The driver experiences a normal / high brake pedal but the vehicle will not decelerate at the expected rate no matter how hard the pedal is depressed. Vapour Lock - When the brakes are overheated the resultant heat transfers through the metal components of the wheel cylinder or caliper and boils the brake fluid. A gas vapour bubble is produced in the wheel cylinder or caliper displacing fluid back towards the master cylinder and the next depression of the brake pedal will allow the pedal to "go to the floor". Dry Boiling Point - This is the boiling point of the fluid when it is new and has negligible moisture absorption. Wet Boiling Point - This is the boiling point of the fluid after it has been exposed to moisture during a specified laboratory test, although most test houses merely add 3.5% water as the test is prolonged and finicky. Dual Brake Systems - These are usually split diagonally and are designed such that if a fault occurs only part (usually 50%) of the braking force is affected. Vapour lock in one brake will cause only partial brake loss, in these cases only one front brake would be operational and an inexperienced driver could easily cause an accident. | ||

So if every vehicle manufacturer used the miracle stuff General Motors and Ford put in their brake reservoirs we would not have to go through this exercise.Part 2. https://www.aa1car.com/library/bfluid.htm

TESTING BRAKE FLUID

Since you can't tell how badly contaminated brake fluid is by its appearance alone (unless the fluid is full of rust or is muddy brown), the fluid should be tested unless you are changing it for preventive maintenance or as part of a brake job.

There are three ways to check the condition of the brake fluid:

.

- An optical refractometer will clearly show the amount of moisture in the brake fluid. A small drop of fluid is placed in the tester, then the tester is held up to a light to read the amount of contamination. This tester is extremely accurate and shows both the percent of moisture and the fluid's boiling point. A source for this type of tool is Misco or Reichert.

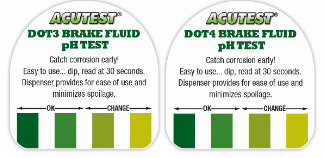

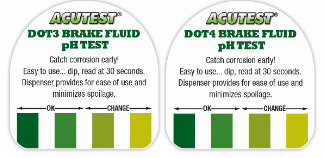

- Chemical test strips. A chemical test strips made by Acustrip Company Inc. and Phoenix Systemscan be used to test the condition of your brake fluid. The test strips change color to reveal the condition of the fluid. If the fluid tests "bad" or "borderline" you should change the fluid.

Acustrip makes two different types of test strips to check the pH of the fluid and moisture content. Phoenix Systems test strips check the level of copper in the fluid. When copper levels reach 100, it indicates the corrosion inhibitors in the fluid are low and that the remaining service life of the brake fluid is limited. If the copper level is 200 or higher, the corrosion inhibitors are worn out and the fluid needs to be changed now.

- Electronic brake fluid testers measure the fluid's boiling temperature. The test takes only about a minute and is quite accurate. If the fluid's boiling temperature is getting dangerously low, replacement is recommended to minimize the risks of pedal fade caused by fluid boil. Sources for electronic brake fluid testers include Alba Diagnostics, MISCO and OTC.

CHANGE BRAKE FLUID

When the fluid is changed, use the type of brake fluid (DOT 3 or 4) specified by the vehicle manufacturer. The cap on the fluid reservoir will usually indicate what type of brake fluid is required. You can also find this information in your Owners Manual (look under brake fluid).

As any brake fluid supplier will tell you, brake fluid is NOT a generic product. Just because a fluid meets the minimum DOT 3 or DOT 4 specifications does not mean it can tolerate moisture or provide the same degree of corrosion protection as another brand of fluid. The wet and dry boiling points of any given brand of brake fluid will depend on the additives in the fluid. Dry boiling temperatures for commonly available DOT 3 brake fluids may range from just over 400 degrees up to 573 degrees F, which is quite a spread. Wet boiling temperatures for DOT 3 fluids don't vary as much, ranging from 284 to 313 degrees F. All of these brake fluids meet the minimum DOT requirements as well as OEM requirements, but obviously a fluid that has a higher dry and wet boiling temperature provides a greater margin of safety and heat resistance.

As for differences in DOT 4 brake fluids, advertised dry boiling temperatures can range from a low of 446 to a high of 646 degrees F depending on the brand. Wet boiling temperatures for DOT 4 fluids are typically in the 300 to 400 degree range, with some being over 430 degrees F. Again, there is quite a range in performance depending on the brand.

There are also high temperature glycol based DOT 5.1 brake fluids (not to be confused with DOT 5 which is silicone based). The dry boiling temperature rating for DOT 5.1 is 518� F or higher, and the wet boiling temperature rating is 375� F or higher. Some racing brake fluids exceed the dry boiling temperature rating, but may only meet the wet boiling temperature requirements for DOT 3 fluid (284 degrees).

If you want to see a detailed comparison of brake fluid performance specifications and prices by brand name, see this Brake Fluid Comparison Chart compiled by Matt Robertson. Matt researched the wet and dry boiling points for each brand listed, and even included the unit price and per ounce price so you can compare one brand of brake fluid to another.

So the next time you are inspecting or servicing your brakes, be sure to check the condition of the fluid as well as the fluid level in the master cylinder. If you add or change fluid, use type of fluid specified by the vehicle manufacturer (DOT 3 or 4) and use the highest quality fluid you can get. And above all, remember the benefits of changing the brake fluid for preventive maintenance

Brake systems are designed for the different grades of brake fluid used. Testing is possible but it is no different to having a Sell by Date on Food or testing it before eating or throwing it away.So if every vehicle manufacturer used the miracle stuff General Motors and Ford put in their brake reservoirs we would not have to go through this exercise.

As an alternative every MOT test centre/service department could check the moisture/additive level in the brake fluid, again avoiding unnecessary replacement by simply testing the fluid using easily obtainable devices.

But of course where is the ongoing profit in that.

The only time Vw will take the pads out is to replace them. In fact that’s probably the first time they will take the wheels off.I'm concerned that in the three years the wheels have yet to be taken off by VW and the Pads have not been out to clean up the calipers.I have now done about 35K so it's high time to do this work.

The VW California Club is the worlds largest resource for all owners and enthusiasts of VW California campervans.