Puncture fire and charging fire are different:

Puncture file is battery physical being short ( car crash etc. ) You can easilly avoid by adding enough padding (wood/metal panel of your choice) and fully secure the battery to avoid that.

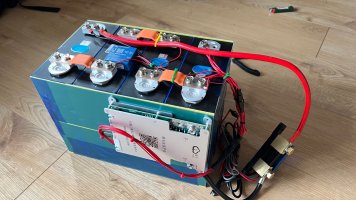

Charging fire is more or less charger issue/ BMS issue related. I use JIKONG 300A bms per 12v 314AH battery pack. I'm just using 8kwh pack to store the energy but I only use a victron 1200w inverter as I dont use very big appliance.

With a good BMS like JIKONG, if you have single cell exceed the max cell value, all charging shut down(which is what most the charging fire caused). Also you have to have active and passive balancing function, my BMS has 3A active balance. But based on the IR value I bought the EVE 314 from (

www.fogstar.co.uk) they seems to be very consistant grade A cell, so I'm not expecting the active balance to kick in a lot of the time. That said with good A cell and good BMS you are on pretty solid safe system. Also this is Lifepo4 not Li-ion so much safer, you will be able to see if a cell is going worse everything is on monitor there is no chance of charing it into a fire.

You need to know what you are doing, basically when you make the pack isolate the + and - make sure they are not touching eachother at any occasion, when you full turn left or right or emergency brake, just make sure all wiring is tidy secured with enough isolation, also fuse it. Then after that the only thing can catch fire is short on a single cell