Almost bought a california

Just finished installing a 100W solar panel and thought there might be some interest in a DIY option - I did see the post by MCEv (Moxie) asking for experience of the Solar Campers Solution but didn't want to hijack his post as the DIY route won't be for everyone and by all accounts the Solar Campers Solution is very good if you want a ready to fit kit.

Total price was just under £300 so not cheap! I loved the Califaktur solar module and the AMAG solution but the prices were way out of my reach and so got a local sheet metal firm to fold a mounting panel for me. I managed to find a suitable curly cable for under £20 but after ordering the solar panel and the controller I discovered that the company only had orange cables in stock so I had to get a one off made at great expense by a super helpful company in Ireland (£61 after carriage and taxes!)

I order to keep the roof neat I had to chop the plugs off the solar panel - I did test it first but needless to say I suspect this will negate any warranty LOL

I opted of a 100W Renogy panel and it was giving 50W here at 5:00 on an April evening so happy with that!

I expected the cable route would be straight forward - it was in the end but the back end is double skinned and so it didn't end up taking the expected route.

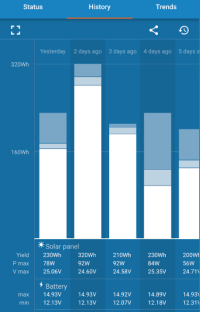

I opted for the 75v, 15W controller incase I fit more panel(s). still overkill I suspect but it's a very nice bit of kit and has an App to monitor and log the solar and battery parameters.

Happy to share the panel mount drawing if anyone else fancies having a go ;-)

Total price was just under £300 so not cheap! I loved the Califaktur solar module and the AMAG solution but the prices were way out of my reach and so got a local sheet metal firm to fold a mounting panel for me. I managed to find a suitable curly cable for under £20 but after ordering the solar panel and the controller I discovered that the company only had orange cables in stock so I had to get a one off made at great expense by a super helpful company in Ireland (£61 after carriage and taxes!)

I order to keep the roof neat I had to chop the plugs off the solar panel - I did test it first but needless to say I suspect this will negate any warranty LOL

I opted of a 100W Renogy panel and it was giving 50W here at 5:00 on an April evening so happy with that!

I expected the cable route would be straight forward - it was in the end but the back end is double skinned and so it didn't end up taking the expected route.

I opted for the 75v, 15W controller incase I fit more panel(s). still overkill I suspect but it's a very nice bit of kit and has an App to monitor and log the solar and battery parameters.

Happy to share the panel mount drawing if anyone else fancies having a go ;-)