burnercan

Lifetime VIP Member

A question for the suspension geometry gurus among you, but first a bit of background.

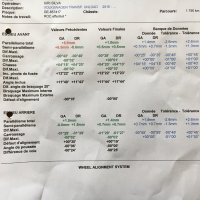

As I mentioned in another thread, in glaring act of unawareness, I recently blew a sidewall out on my nice new bus. While reversing out of a parking stall and avoiding a post on the left side of the vehicle, I didn't notice that the post was sitting on a big square concrete footing. About 25 cm high and sticking out about the same from the edge of the post, I connected with it when the steering wheel was on nearly full right lock. I was moving slowly but the ~3T came to an immediate halt with an almighty bang. This resulted in the blown sidewall, me hanging my head in shame and the steering wheel being cocked off to the left about 10° when travelling in a straight line. 200km on the clock. Give me my Dunce Cap.

The tech doing the alignment was very nice chap and I hung around the lift while he was working. I explained the above story to him and he assured me there is no visible and likely no hidden damage. I had previously crawled around it myself with light and mirror, had a good look at all of the attach points and came to the same conclusion.

So the question is this:

What gives to allow the alignment to move during an impact but not sustain any damage to a component?

In my head, something had to bend in order for the alignment to be thrown off though I must be wrong. The toe was out by quite a lot, and the entire toe system is geared or threaded together from what I can tell. Short of stripping a thread on a tie rod end or a tooth on the rack, I can't see what else can move. The tech adjusted the tie rod ends to correct it.

Edit for typo.

As I mentioned in another thread, in glaring act of unawareness, I recently blew a sidewall out on my nice new bus. While reversing out of a parking stall and avoiding a post on the left side of the vehicle, I didn't notice that the post was sitting on a big square concrete footing. About 25 cm high and sticking out about the same from the edge of the post, I connected with it when the steering wheel was on nearly full right lock. I was moving slowly but the ~3T came to an immediate halt with an almighty bang. This resulted in the blown sidewall, me hanging my head in shame and the steering wheel being cocked off to the left about 10° when travelling in a straight line. 200km on the clock. Give me my Dunce Cap.

The tech doing the alignment was very nice chap and I hung around the lift while he was working. I explained the above story to him and he assured me there is no visible and likely no hidden damage. I had previously crawled around it myself with light and mirror, had a good look at all of the attach points and came to the same conclusion.

So the question is this:

What gives to allow the alignment to move during an impact but not sustain any damage to a component?

In my head, something had to bend in order for the alignment to be thrown off though I must be wrong. The toe was out by quite a lot, and the entire toe system is geared or threaded together from what I can tell. Short of stripping a thread on a tie rod end or a tooth on the rack, I can't see what else can move. The tech adjusted the tie rod ends to correct it.

Edit for typo.

Last edited: