- Home

- Forums

- VW California T5 T6 & T6.1 Specific Sections

- VW California T5,T6 & T6.1 Specific Sections

- Elevating Roof

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

WelshGas

Retired after 42 yrs and enjoying Life.

Super Poster

Lifetime VIP Member

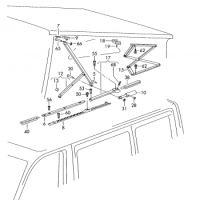

It seems as if the bolt has come undone.View attachment 127699

Solutions or spare parts required if anyone has experienced this issue

Firstly, I would remove bolt and see if it will screw into the threaded hole correctly .

If so just replace it through the casting and tighten up, Possibly using some thread lock.

Now if the bolt won’t screw into the threaded hole then we have a problem.

What year is your vehicle?

deltheblue

Hi Welsh gas its 2004 it looks like the nut which was cast into the frame has popped out of its casting so I think we have a problemIt seems as if the bolt has come undone.

Firstly, I would remove bolt and see if it will screw into the threaded hole correctly .

If so just replace it through the casting and tighten up, Possibly using some thread lock.

Now if the bolt won’t screw into the threaded hole then we have a problem.

What year is your vehicle?

deltheblue

Just the paint has come off looks worse on the photo than in real lifeIt looks like you have been hitting it with a big hammer? Any reason why.

deltheblue

That's helpful cheersI’d say that’s bust

deltheblue

I'll have a look at that thanks I'm just looking at it again and it does look like a hammer has been used on it, only got it back on wednesday after getting some corrosion sorted in the front roof panel

C

Crasher

Who did the corrosion my 09 needs a bit doing .Where abouts are you as I have access to a tool if you need to use it at mine.I'll have a look at that thanks I'm just looking at it again and it does look like a hammer has been used on it, only got it back on wednesday after getting some corrosion sorted in the front roof panel

deltheblue

I'm I liverpool mate, a friend of mine did the repairs on the front roof panel which was bubbling and flaking offWho did the corrosion my 09 needs a bit doing .Where abouts are you as I have access to a tool if you need to use it at mine.

C

Crasher

My daughter is studying in liverpool .I'm I liverpool mate, a friend of mine did the repairs on the front roof panel which was bubbling and flaking

Does he do work on others and is it a pro job where they treat the aluminium etc.

deltheblue

I'm not sure how it's been done to be honest we discussed the anti corrosion painting of the aluminium before he took it and he had it for 4 weeksMy daughter is studying in liverpool .

Does he do work on others and is it a pro job where they treat the aluminium etc.

C

Crasher

Hope you get it sorted.

Hope you get sorted if not message me will try get tool one weekend when visit her.I'm not sure how it's been done to be honest we discussed the anti corrosion painting of the aluminium before he took it and he had it for 4 weeks

deltheblue

I'm looking at using a strong epoxy to reset the nut into place and tighten the bolt back into it as it looks like it's just the cover over the roof runnerI have nursert tools in maryport Cumbria, what thread is it?

deltheblue

you dont think I could take the nut off and reset it with a good epoxy? I'm open minded I just thought the cover will not be under any pressure so should hold with the epoxyLooks like the nut has come away with the bolt, don’t think epoxy is going to work. As said nutsert is the way to go.

Kimbo

VIP Member

How well do you know this geyser that worked on the roof?, might just have come away due to rusting but might have got ripped out with an over enthusiastic attempt to remove the seized bolt if that roof needed to be removed for some reason , just sayingyou dont think I could take the nut off and reset it with a good epoxy? I'm open minded I just thought the cover will not be under any pressure so should hold with the epoxy

kurienp

Super Poster

VIP Member

In addition to all that suggested above, I would:View attachment 127699

Solutions or spare parts required if anyone has experienced this issue

1. the nut and bolt look rusted. that rust may be there on the roof panel where the nut/bolt perches. I would take off as much of the fitments in that area to look under.

2. Treat all areas around it with rust remover and then rust proof that area depending on the kind/type of metal where that nut perches.

3. Either weld or epoxy (choose the easiest method, most probably epoxy) the nut to where it belongs wait for it it to cure and then clean all parts and assemble everything back.

Cleaning the existing areas correctly will be very important for a good fix/solution.

Kimbo

VIP Member

A similar captive nut arrangement is used for the three bolts under the bonnet holding the top of the front strut and if you've ever tried to remove a shock assembly, you'll already know what an absolute pain it is to get them out after they've parted company with the top bearing assembly and they are stuck up inside the shock turret.

S

secret lemonade drinker

VIP Member

M3 - M12 Hand Nut Riveter Nut Sert Tool Fastener Fastening Riveting Kit 3 - 12mm | DIY at B&Q

Professional nut sert tool for commercial or occasional use M3 - M12 Hand Nut Riveter Heavy duty nut sert tool Suitable for all types of materials including aluminium / steel etc... Nut sert ranging from M3 - M12 Suitable for most materials that cannot be tapped or welded Requires access to...

www.diy.com

This is the nut sert Kit I have, It is brilliant and good for up to M8 Nutserts, the rivet gun one can be prone to inserting the nuts in a twisted fashion. I don't think Epoxy will hold. Aftermarket pop top roofs use threaded steel stock inserted in the frame where you have a nut.

Similar threads

About us

The VW California Club is the worlds largest resource for all owners and enthusiasts of VW California campervans.