steve_b

Lifetime VIP Member

Thanks, a picture would be interesting. My suspicion is that there are many possible failure modes - the devices seem to have 2 active states which could be detected by the control unit.

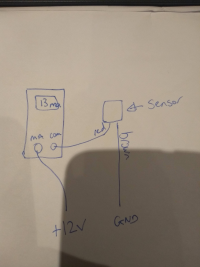

I am assuming that there is a resistor in the control unit and it measures the voltage across the hall sensor, which means that each sensor has 4 possible states - two good and 2 bad. Note that I am guessing at the voltage numbers below, they will not be correct - they are for example only.

0-1V (broken wire, entirely duff unit, shorted to ground) - it knows the sensor is faulty

between 1 and 2.5V - a normal reading for a sensor without any large metal objects (the piston end) nearby

between 2.5 and 5V - a normal reading for a sensor with a large object nearby (piston end nearby)

Over 5V - we know this is fault, maybe shorted to +12v or whatever

So from 1 sensor / 1 pair of wires we can get 4 states - two of which are definitive errors. (voltage too high or voltage too low)

Then combining the sensors there are other possible error combinations, for example

Left side rear sensor open, right side closed . This maybe is allowed to persist for a few seconds if the roof is not opening absolutely straight but a long term mismatch is obviously wrong. Same for the front sensors - in a perfect world both would change state at the same time.

Front sensor showing roof open and back sensor showing roof closed. Again a logical impossibility , this should thrown an error.

Shame we can't dig deeper into the control unit t ask it exactly WHY it thinks there is a problem.

I am assuming that there is a resistor in the control unit and it measures the voltage across the hall sensor, which means that each sensor has 4 possible states - two good and 2 bad. Note that I am guessing at the voltage numbers below, they will not be correct - they are for example only.

0-1V (broken wire, entirely duff unit, shorted to ground) - it knows the sensor is faulty

between 1 and 2.5V - a normal reading for a sensor without any large metal objects (the piston end) nearby

between 2.5 and 5V - a normal reading for a sensor with a large object nearby (piston end nearby)

Over 5V - we know this is fault, maybe shorted to +12v or whatever

So from 1 sensor / 1 pair of wires we can get 4 states - two of which are definitive errors. (voltage too high or voltage too low)

Then combining the sensors there are other possible error combinations, for example

Left side rear sensor open, right side closed . This maybe is allowed to persist for a few seconds if the roof is not opening absolutely straight but a long term mismatch is obviously wrong. Same for the front sensors - in a perfect world both would change state at the same time.

Front sensor showing roof open and back sensor showing roof closed. Again a logical impossibility , this should thrown an error.

Shame we can't dig deeper into the control unit t ask it exactly WHY it thinks there is a problem.