- Home

- Forums

- VW California T5 T6 & T6.1 Specific Sections

- VW California T5,T6 & T6.1 Specific Sections

- Elevating Roof

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

steve_b

Lifetime VIP Member

Excellent news. They are only 2 wire so presumably must work like an ABS sensor which controls a current which changes when near a magnet, so the control unit can detect positively open and closed and broken. If you are going to chuck them in the bin could I ask you to post one or more to me so that I can try and decypher how it works it a bit more please? Might help future testing and diagnostics.

Thanks

Steve

Thanks

Steve

KGCali

Retired and still young at heart!

Lifetime VIP Member

@steve_b You may find the datasheet for the Hall Sensor CAT-ATS0050 from the manufacturer TE Connectivity useful...Excellent news. They are only 2 wire so presumably must work like an ABS sensor which controls a current which changes when near a magnet, so the control unit can detect positively open and closed and broken. If you are going to chuck them in the bin could I ask you to post one or more to me so that I can try and decypher how it works it a bit more please? Might help future testing and diagnostics.

Thanks

Steve

cylinder hall switch

The cylinder hall switch measures piston position of hydraulic cylinder for convertible roofs.

Lambeth Cali

Super Poster

VIP Member

Sure can you message me your address?Excellent news. They are only 2 wire so presumably must work like an ABS sensor which controls a current which changes when near a magnet, so the control unit can detect positively open and closed and broken. If you are going to chuck them in the bin could I ask you to post one or more to me so that I can try and decypher how it works it a bit more please? Might help future testing and diagnostics.

Thanks

Steve

steve_b

Lifetime VIP Member

can do but looks like your profile settings don't allow it? or maybe you have to be a paid up member - not sure how that works...Sure can you message me your address?

-edit- will it let you change who can "start conversations" with you here:

set to members only?

Last edited:

WelshGas

Retired after 42 yrs and enjoying Life.

Super Poster

Lifetime VIP Member

I believe “Conversations “ is a VIP members privilege.can do but looks like your profile settings don't allow it? or maybe you have to be a paid up member - not sure how that works...

-edit- will it let you change who can "start conversations" with you here:

set to members only?

steve_b

Lifetime VIP Member

@Lambeth Cali I have "followed you" and allowed my followings to see my profile. What do you see if you click on my monkey self?

Lambeth Cali

Super Poster

VIP Member

I’ve just subscribed for 2 years so perhaps that might help.@Lambeth Cali I have "followed you" and allowed my followings to see my profile. What do you see if you click on my monkey self?

Lambeth Cali

Super Poster

VIP Member

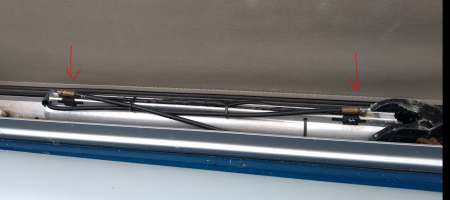

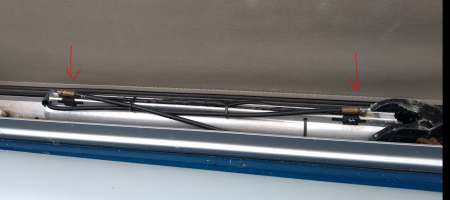

By the way they are 2 wires but I noticed the front and back sensors appeared to be connected to each other also. See wires in pictureExcellent news. They are only 2 wire so presumably must work like an ABS sensor which controls a current which changes when near a magnet, so the control unit can detect positively open and closed and broken. If you are going to chuck them in the bin could I ask you to post one or more to me so that I can try and decypher how it works it a bit more please? Might help future testing and diagnostics.

Thanks

Steve

V

vwbob

VIP Member

- Messages

- 32

I Think the two wires connected together is the live feed to both sensors. Again another guess the other wire is the signal wire.Glad you managed to fix it will be pleased to reading your write up. This seems to be a common issue and to be able to solve it with a bit of DIY saves a lot of money.

steve_b

Lifetime VIP Member

I have done some preliminary tests on the two sensors you shipped me (thanks @lambeth_cali) , the short answer is that they both seem to "work" but as far as I can tell they are going to be an absolute sod to test in situ, or to fool the roof control mechanism what the state is. (i.e. if the roof refuses to open with error 1000 or whatever). I was hoping that they would be sensitive enough so that a magnet placed nearby would operate them but I can only get any effect in direct contact.

I will write up what I have found later but sadly no quick win

I will write up what I have found later but sadly no quick win

Ozzy Pete

From looking at the magnificent work you have done it would give great confidence to many on here to give it a try. Really in a way there’s not a lot to lose only about a hundred quid. The hydraulic pipes being in the way looks worrisome but you did it so we know it can be done. I was just wondering, as this is almost certainly a problem caused by water ingress over a long period of time could it have been stopped by VW sealing the hall sensor with Silicone. Either a clear silicone from a tube or maybe a silicone spray. Any ideas if this might work?

steve_b

Lifetime VIP Member

In one of the sensors that @Lambeth Cali sent me the magnet had actually rusted and broken out of the plastic holder - and the pictures he posted above show another one with white powdery reside so I agree that water ingress is almost certainly a cause.

You can get to them very easily with a T25 screwdriver (one of the few on this vehicle that isn't a 12 point spline head) and have a look - one (rusted..) T25 bolt holds the plastic cap on here - between the front and back arms.

then you can see the front and rear sensors underneath. They are smaller than I imagined and sit under the brassy coloured hydraulic pipe attachment at each end of the piston. They must work when they detect the metal of the piston passing underneath so the states should be

Front one only activated (roof fully open)

None Activated (roof between open and closed)

Back one activated (roof fully closed)

I guess the control panel "error 1000" is perhaps when either it sees the sides in inconsistent states (i.e. front open back closed) or both front and back activated at the same time, or maybe a short circuit or wrong current as they seem to work by having two valid states so the control unit could theoretically detect states (voltage levels) outside of the two known normal ones.

You can get to them very easily with a T25 screwdriver (one of the few on this vehicle that isn't a 12 point spline head) and have a look - one (rusted..) T25 bolt holds the plastic cap on here - between the front and back arms.

then you can see the front and rear sensors underneath. They are smaller than I imagined and sit under the brassy coloured hydraulic pipe attachment at each end of the piston. They must work when they detect the metal of the piston passing underneath so the states should be

Front one only activated (roof fully open)

None Activated (roof between open and closed)

Back one activated (roof fully closed)

I guess the control panel "error 1000" is perhaps when either it sees the sides in inconsistent states (i.e. front open back closed) or both front and back activated at the same time, or maybe a short circuit or wrong current as they seem to work by having two valid states so the control unit could theoretically detect states (voltage levels) outside of the two known normal ones.

Lambeth Cali

Super Poster

VIP Member

It’s difficult to say. The tape over the wire was very basic and kind of surprising. The sensors aren’t really protected much. The plastic cover has an open notch in the side which seemed odd. Perfect for letting rain in. I wondered if it was needed for air to escape the hydraulics but is that how they work?From looking at the magnificent work you have done it would give great confidence to many on here to give it a try. Really in a way there’s not a lot to lose only about a hundred quid. The hydraulic pipes being in the way looks worrisome but you did it so we know it can be done. I was just wondering, as this is almost certainly a problem caused by water ingress over a long period of time could it have been stopped by VW sealing the hall sensor with Silicone. Either a clear silicone from a tube or maybe a silicone spray. Any ideas if this might work?

I’d say it would be easy for water to get to the sensors from rain and/or capillary action.

Loz

Super Poster

Lifetime VIP Member

Maybe some electricians magic gel?

Ozzy Pete

I’m sure that a spray with a good silicone would protect the Sensor terminals but would need to look into it further. I’m sure it wouldn’t do any harm and maybe prevent this from happening in the future. It’s worth thinking about.It’s difficult to say. The tape over the wire was very basic and kind of surprising. The sensors aren’t really protected much. The plastic cover has an open notch in the side which seemed odd. Perfect for letting rain in. I wondered if it was needed for air to escape the hydraulics but is that how they work?

I’d say it would be easy for water to get to the sensors from rain and/or capillary action.

Ozzy Pete

This is really worth looking into as a few minutes work sealing the Sensors could mean either hundreds of pounds saved or many hours of work to do it yourself. Most people wouldn’t have the confidence to undertake a complicated job like this so are left with no option but to let the main dealer relieve you of £1500.Maybe some electricians magic gel?

ArunAlec

Super Poster

VIP Member

Maybe ignition sealer spray……. If it’s still available!I’m sure that a spray with a good silicone would protect the Sensor terminals but would need to look into it further. I’m sure it wouldn’t do any harm and maybe prevent this from happening in the future. It’s worth thinking about.

Ozzy Pete

I’m sure that something along those lines would be perfect. The way the roof mechanism has been designed and of coarse the amount of times the roof is “Up” while it’s raining is going to determine how long it will be before the sensors actually fail. The combination of A magnet, electrical current and moisture and it’s only a matter of time before they fail.I wonder if anyone else has tried this or do they use this sealer when doing sensor repairs.Maybe ignition sealer spray……. If it’s still available!

I

illwizod

Thank you Club members - all very helpful information and I successfully managed the repair in a couple of hours.

Similar threads

- Home

- Forums

- VW California T5 T6 & T6.1 Specific Sections

- VW California T5,T6 & T6.1 Specific Sections

- Elevating Roof

About us

The VW California Club is the worlds largest resource for all owners and enthusiasts of VW California campervans.